Top Selling Metal Flower Vase Latest Design For Home And Garden Use Luxury Product Home Decor Flower Vase Gold Color Set Of 3

(0

reviews)

Estimate Shipping Time:

3 Days

Sold by:

Inhouse product

Inhouse product

Price:

$62.00

/Pc

Refund:

Share:

Top Selling Products

-

G2000 Women Belted Dress

$53.90

Product Description

Specification

item | value |

Occasion | Christmas |

Size | M |

Function | Tabletop Vase |

Design Style | Modern |

Place of Origin | India |

Uttar Pradesh | |

Brand Name | AWO |

Material | Aluminium |

Product Name | Flower Vase |

Material | Alumnium |

Usage | Home Decoration Wedding Decoration |

Color | Customized Colors |

Size | Customized Size |

Design | Accept Customized Designs |

MOQ | 100pcs |

Logo | Customized Logo Acceptable |

Packing | Customized Packing |

OEM ODM | AVAILABLE |

Manufacturing Technique

Polishing Process

Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment, leaving a clean surface with a significant specular reflection.

Polishing is often used to enhance the appearance of an item, prevent contamination of instruments, remove oxidation, create a reflective surface, or prevent corrosion in pipes. In metallography and metallurgy, polishing is used to create a flat, defect-free surface for examination of a metal's microstructure under a microscope. Silicon-based polishing pads or a diamond solution can be used in the polishing process. Polishing stainless steel can also increase its sanitary benefits.

Electro Plating

Electroless deposition (ED) or electroless plating is defined as the autocatalytic process through which metals and metal alloys

are deposited onto conductive and nonconductive surfaces.These nonconductive surfaces include plastics, ceramics, and glass etc.

which can then become decorative, anti-corrosive, and conductive depending on their final functions. Electroplating unlike electroless deposition only deposits on other conductive or semi-conductive when a external current is applied. Electroless deposition deposits metals onto 2D and 3D structures such as screws, nanofibers, and carbon nanotubes unlike other plating methods such as Physical Vapor Deposition ( PVD), Chemical Vapor Deposition (CVD), and electroplating which are limited to 2D surfaces.

are deposited onto conductive and nonconductive surfaces.These nonconductive surfaces include plastics, ceramics, and glass etc.

which can then become decorative, anti-corrosive, and conductive depending on their final functions. Electroplating unlike electroless deposition only deposits on other conductive or semi-conductive when a external current is applied. Electroless deposition deposits metals onto 2D and 3D structures such as screws, nanofibers, and carbon nanotubes unlike other plating methods such as Physical Vapor Deposition ( PVD), Chemical Vapor Deposition (CVD), and electroplating which are limited to 2D surfaces.

Hydraulic Press

Only small-diameter tubing (which more easily resists pressure) is needed if the pump is separated from the press cylinder. Hydraulic presses are commonly used for forging, clinching, molding, blanking, punching, deep drawing, and metal forming operations. Hydraulic presses are also used for stretch forming, rubber pad forming, and powder compacting.The hydraulic press is advantageous in manufacturing, it gives the ability to create more intricate shapes and can be economical with materials A hydraulic press will take up less space compared to a mechanical press of the same capability. The hydraulic press depends on (Pascal's principle).The pressure throughout a closed system is constant. One part of the system is a piston acting as a pump, with a modest mechanical force acting on a small cross-sectional area; the other part is a piston with a larger area which generates a correspondingly large mechanical force.

Product packaging

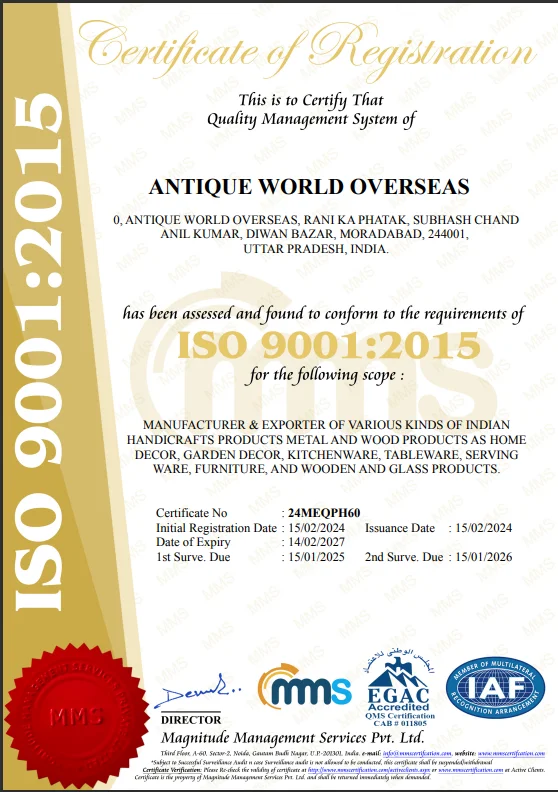

Certifications

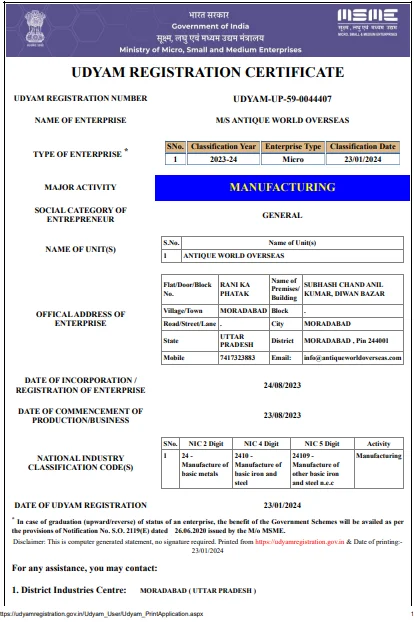

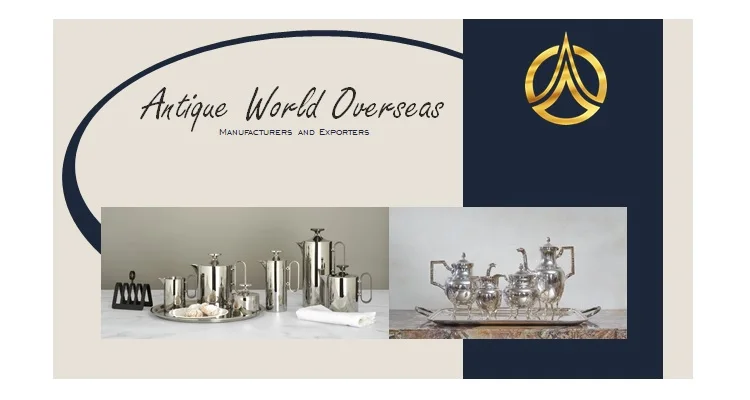

Company Profile

Why Choose Us

Exhibition

FAQ

Q: How can we get sample to test quality before placing larger order?

Ans: We are glad to inform that Our Sample department can dispatch sample/samples to check the quality on customer

DHL/FedEx/UPS/TNT account.

Q: What is the normal lead time?

Ans: For stock items, we will send goods to you within 10-15 days after receiving your payment.

For customized products, the delivery time is 45-60 days after receiving your payment. That is dependent on the total quantity

required.

Q: What is your shipping terms?

Ans: We can arrange shipment by sea or by air according to your requirement. We will help you to choose the best efficient

shipping way according to your detailed requirements.

Q: How do you control the quality?

Ans: We do quality testing before starting the bulk production. Also, there is strict quality control system in place to ensure

good quality to the client. We do quality checks at multilevel of production this helps in getting the top niche quality product

at last. Also, we always request our customers to inspect the goods before shipping.

Q: How to proceed with the order if I have logo to print?

First, we will prepare artwork for visual confirmation, and next we will produce a real sample for your second confirmation. If

sample is ok, finally we will go to mass production

Q: why should you buy from us not from other suppliers?

01. We main produce the Handicraft products for more than 25 years;

02. Factory direct sale: can assure the good quality, at lowest price

03. We have the export rights our self , we can export the goods directly;

04. We have 3 excellent designers, welcome.

Ans: We are glad to inform that Our Sample department can dispatch sample/samples to check the quality on customer

DHL/FedEx/UPS/TNT account.

Q: What is the normal lead time?

Ans: For stock items, we will send goods to you within 10-15 days after receiving your payment.

For customized products, the delivery time is 45-60 days after receiving your payment. That is dependent on the total quantity

required.

Q: What is your shipping terms?

Ans: We can arrange shipment by sea or by air according to your requirement. We will help you to choose the best efficient

shipping way according to your detailed requirements.

Q: How do you control the quality?

Ans: We do quality testing before starting the bulk production. Also, there is strict quality control system in place to ensure

good quality to the client. We do quality checks at multilevel of production this helps in getting the top niche quality product

at last. Also, we always request our customers to inspect the goods before shipping.

Q: How to proceed with the order if I have logo to print?

First, we will prepare artwork for visual confirmation, and next we will produce a real sample for your second confirmation. If

sample is ok, finally we will go to mass production

Q: why should you buy from us not from other suppliers?

01. We main produce the Handicraft products for more than 25 years;

02. Factory direct sale: can assure the good quality, at lowest price

03. We have the export rights our self , we can export the goods directly;

04. We have 3 excellent designers, welcome.

There have been no reviews for this product yet.

Related products

$125.00

American Style Furniture Antique Kitchen Cabinets Self Assemble Kitchen Cabinets

Club Point:

0