Hubcap Performance Automobile Hub Cap Full Rim Cover Accessories For Tesla Model Y 19 Inch Wheel Caps 2018-2024

(0

reviews)

Estimate Shipping Time:

3 Days

Sold by:

Inhouse product

Inhouse product

Price:

$50.01

/Pc

Refund:

Share:

Top Selling Products

-

G2000 Women Belted Dress

$53.90

Contact us

Email: metals_bill@163.com

WhatsApp: +86 15889621354

Phone: +86 15889621354

HubCap Performance Automobile Replacemen Hub cap Full Rim Cover Accessories for Tesla Model Y 19 Inch Wheel Caps 2018-2024

Product Overview

Customization

Contact us

Email: metals_bill@163.com

WhatsApp: +86 15889621354

Phone: +86 15889621354

WhatsApp: +86 15889621354

Phone: +86 15889621354

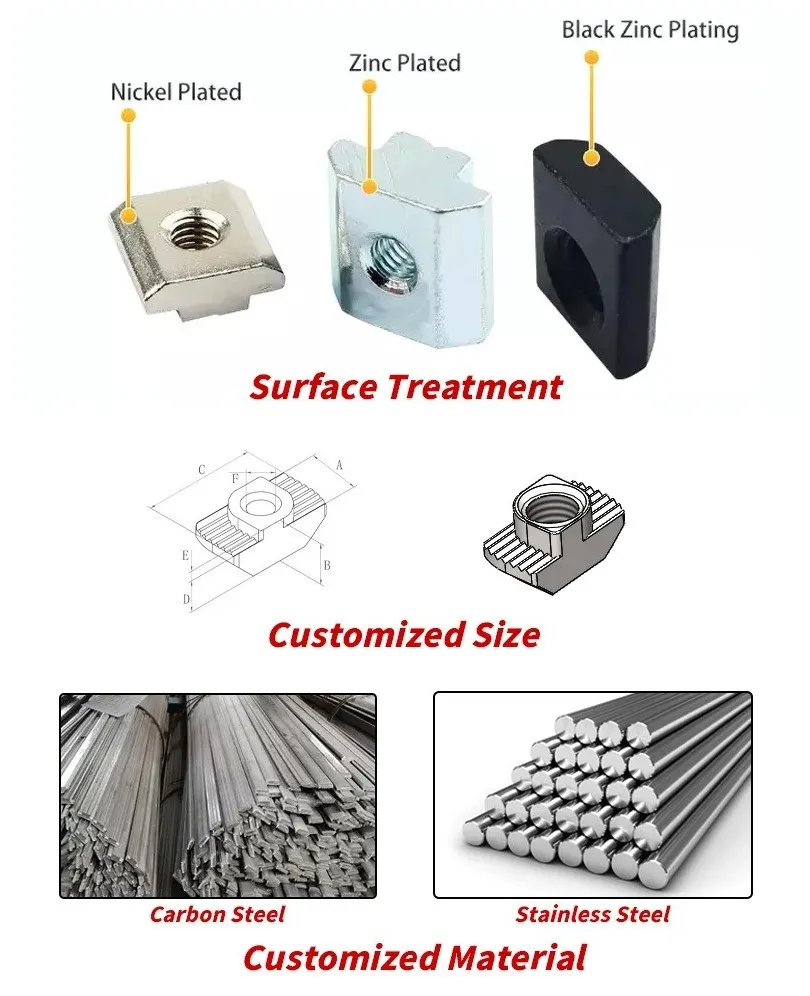

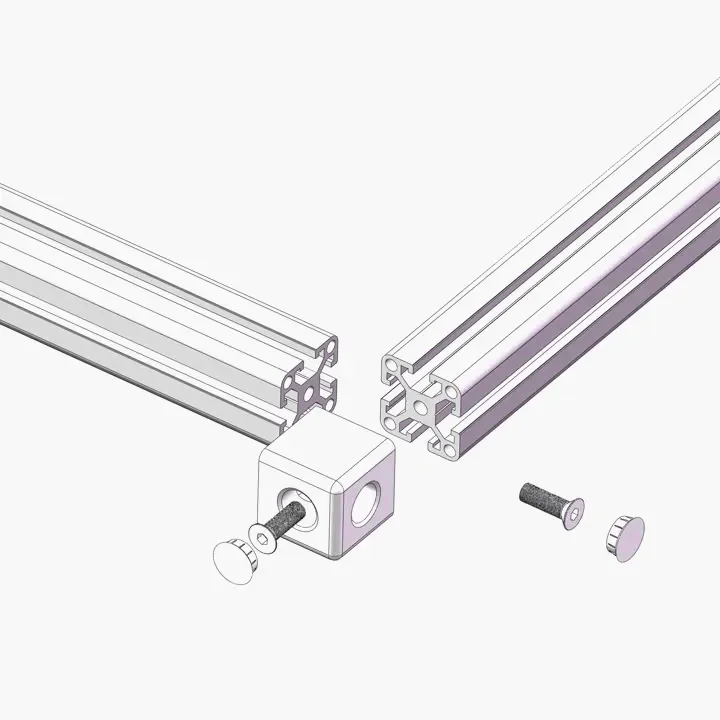

1. Surface Treatment | Zinc plating (environmentally friendly zinc, typically 5-8μm, special: 12μm, Cr³⁺) |

Nickel plating (higher cost, better corrosion resistance) | |

Dacro (Geomet) coating | |

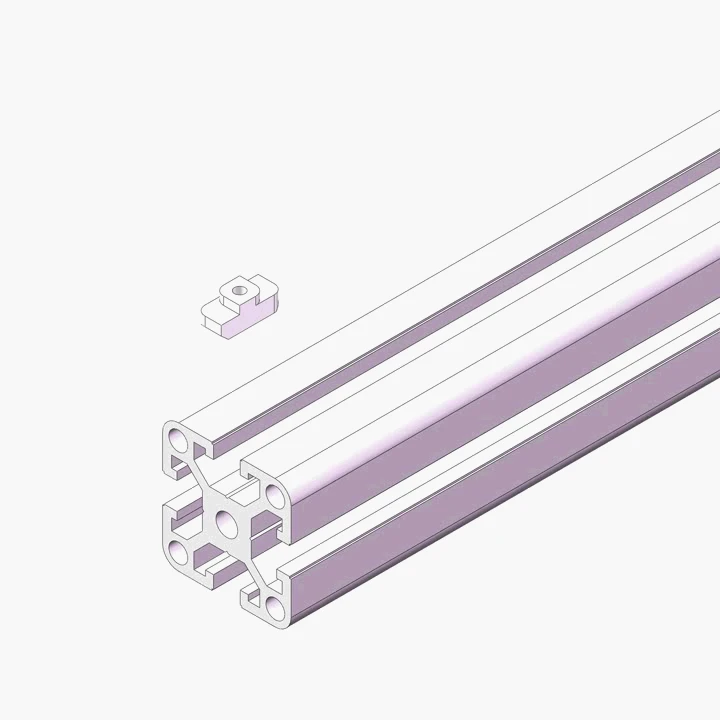

2. Slot Width | Profile 20mm: Slot width 6 or 5mm |

Profile 30mm: Slot width 8 or 6mm | |

Profile 40mm: Slot width 8 or 10mm | |

Profile 45mm: Slot width 10mm | |

3. Step Size | Step height for Slot 10mm: Typically 3.0mm |

Step height for Slot 8mm: Typically 1.5mm | |

4. Material | Standard: 20# steel |

Options: Low carbon steel (Q195, Q235, C1020) or medium carbon steel (35#) | |

Stainless steel options available | |

Grade: 4/6/8/10/12 | |

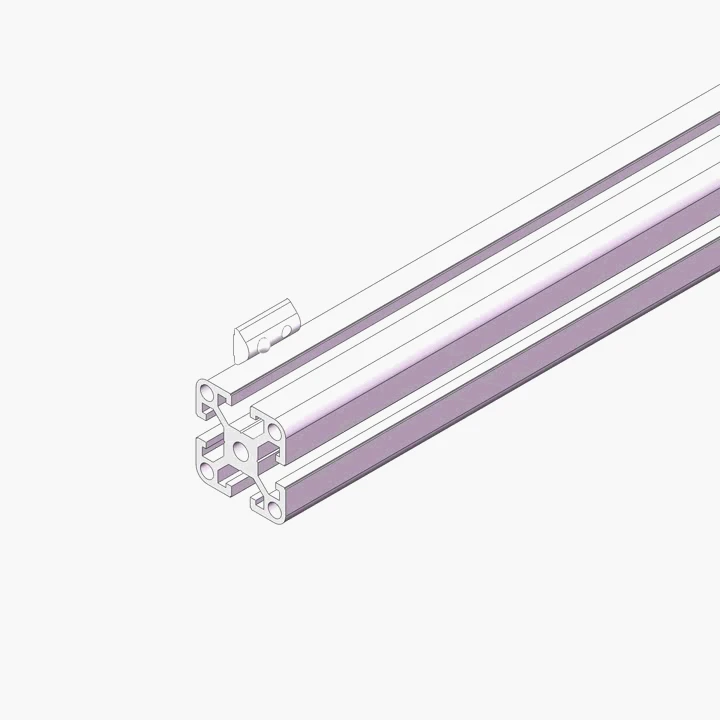

5. Thread | Metric threads (common): M3, M4, M5, M6, M8, M10 |

US threads: 10-32, 1/4-20, 5/16-18 | |

6. Teeth | 2 teeth, 4 teeth, 7 teeth (fine teeth) |

Other options: T-nut, slide-in nut, ball nut, spring-loaded nut, rhombus nut, flange nut | |

7. Raised Dots | Raised dots on T-nut for electrical conductivity |

8. Inspection | 1. Compatibility with profiles |

2. Compliance with thread standards (pre-galvanized: 6G, post-galvanized: 6H) | |

3. For slot width 6 profiles, thread hole size should not exceed M6 | |

4. For slot width 8 profiles, thread hole size should not exceed M8 | |

5. For slot width 10 profiles, thread hole size should not exceed M10 | |

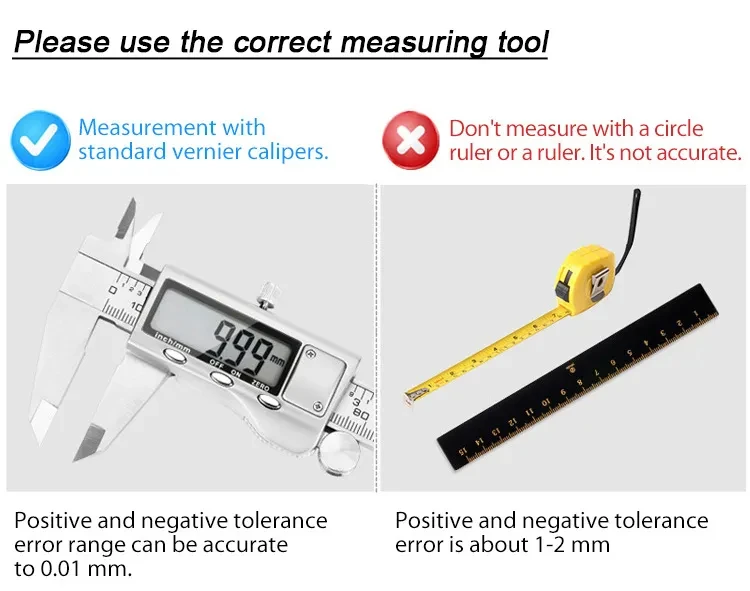

6. Tolerances according to ISO2768-MK |

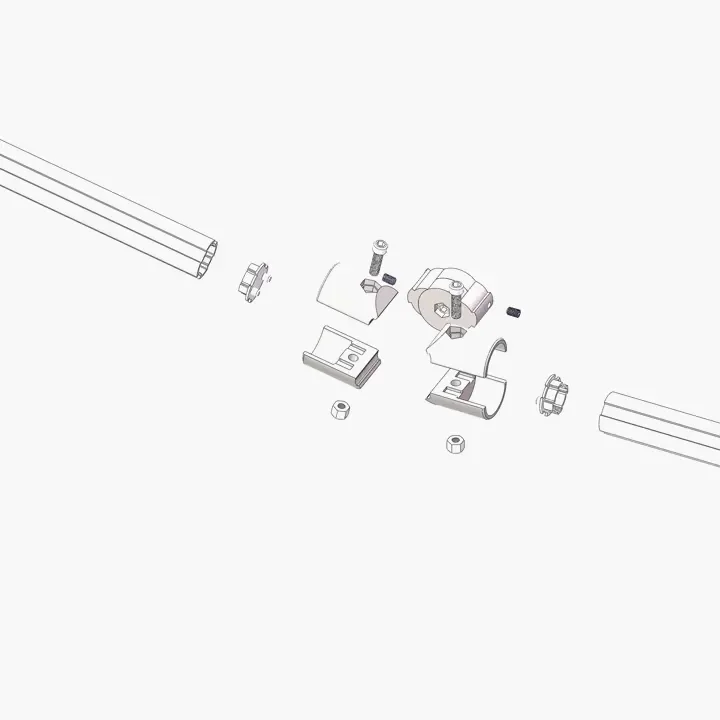

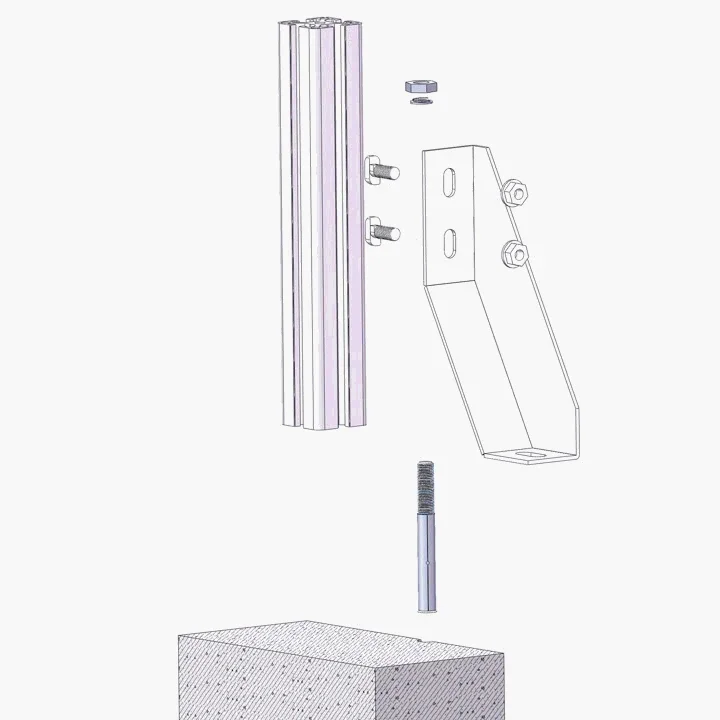

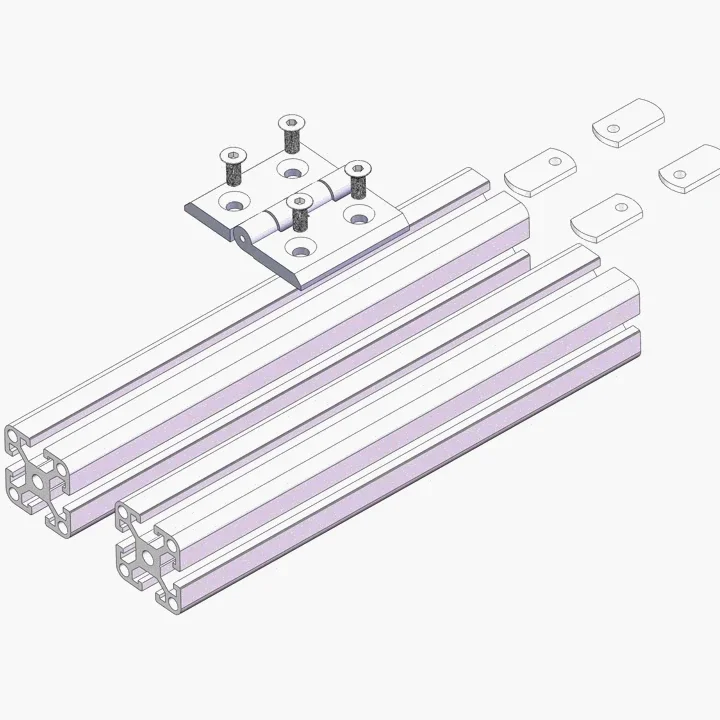

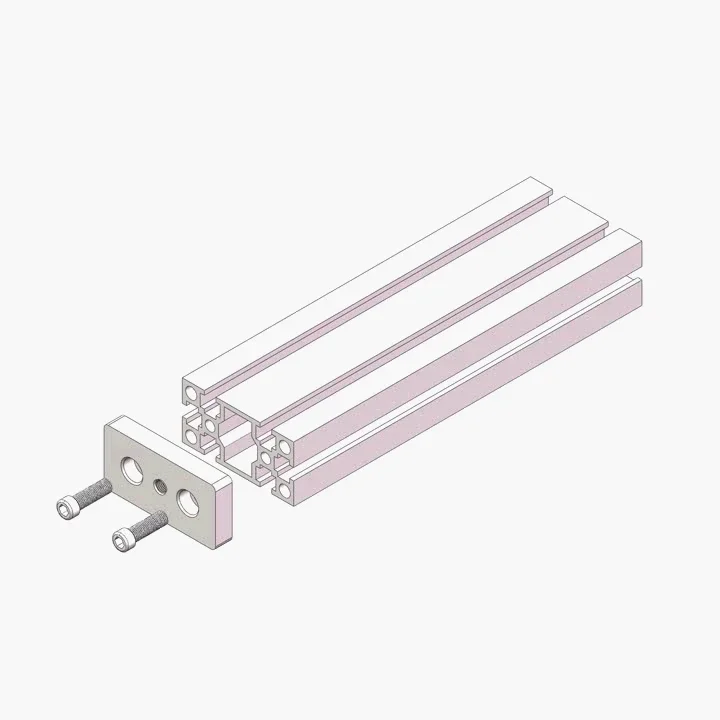

Part of the product demonstration

Company Information

Huizhou Metals Precision Hardware Co., Ltd. was founded in Huizhou , Guangdong , China in 2010 on the simple premise that quality,service, and on-time deliveries were crucial to developing lasting customer relationships. We know how important it is for manufacturers to produce their products consistently without delays or quality issues.

Parts that cost pennies should never cause problems that cost dollars. Over the years, we have found success by maintaining that simple principle and by remaining hyper focused on a long term value over short term gains.

OUR MISSION

We are driven by one all-encompassing mission: to become our customer's absolute best supplier, period. We strive to accomplish this every day by focusing on providing fast response times, extreme urgency in resolving any issues, strict quality controls, and weekly data analysis & forecasting

CUSTOM COLD & HOT HEADED PARTS

CUSTOM PRECISION MACHINED PARTS

CUSTOM SPRINGS & STAMPED PARTS

OUR CUSTOMERS

We are proud to serve our noteworthy customer base that includes manufacturers representing the best of their respective

industries:

industries:

SALES AND SERVICE NETWORK

Packing & Shipping

FAQ

1. who are we?

We are based in Huizhou , Guangdong, China, start from 2010,sell to Western Europe(25.00%),Mid East(10.00%),North

America(25.00%),Eastern Europe(15.00%),South America(15.00%),Southeast Asia(10.00%). There are total about 30-50 people in our

office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;Always final Inspection before shipment;

3.what can you buy from us?

T Nuts,T Slot Nuts,Profile Connectors,Hinges,Angle Brackets

4. why should you buy from us not from other suppliers?

Our Official Promises:

A. Lifetime Quality Warranty

B. 7 days Production lead time

C. Free Samples are available

D. Free Tooling Designing Service

E. More competitive cost control

F. Small OEM order is acceptable

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP;

Accepted Payment Currency:USD,EUR,JPY,GBP,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,Credit Card,PayPal,Western Union,Cash;Language Spoken:English,Chinese

We are based in Huizhou , Guangdong, China, start from 2010,sell to Western Europe(25.00%),Mid East(10.00%),North

America(25.00%),Eastern Europe(15.00%),South America(15.00%),Southeast Asia(10.00%). There are total about 30-50 people in our

office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;Always final Inspection before shipment;

3.what can you buy from us?

T Nuts,T Slot Nuts,Profile Connectors,Hinges,Angle Brackets

4. why should you buy from us not from other suppliers?

Our Official Promises:

A. Lifetime Quality Warranty

B. 7 days Production lead time

C. Free Samples are available

D. Free Tooling Designing Service

E. More competitive cost control

F. Small OEM order is acceptable

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP;

Accepted Payment Currency:USD,EUR,JPY,GBP,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,Credit Card,PayPal,Western Union,Cash;Language Spoken:English,Chinese

There have been no reviews for this product yet.

Related products

$750.00

High Speed 3000W Electric Motorcycle Adults 80km/h Off Road Motorcycle Electric

Club Point:

0

$500.00

SKYTEAM 50CC 125CC 4 stroke PBR MONKEY ZB50 KSR Motorcycle (EEC EURO3 Approval)

Club Point:

0