Custom Die Cast Modle Car Zinc Alloy Aluminium High Pressure Die Cast Car Parts

(0

reviews)

Estimate Shipping Time:

3 Days

Sold by:

Inhouse product

Inhouse product

Price:

$14.50

/Pc

Refund:

Share:

Top Selling Products

-

G2000 Women Belted Dress

$53.90

Custom die casting machine zinc alloy aluminium high pressure die cast car parts

Products Description

Main Process | Sand Casting , Resin Sand Casting, Green Sand Casting, Die Casting, Gravity Casting, Shell Molding, Automatic Molding |

Material | Ductile Iron, Grey Iron, Aluminum or as customer request |

Surface Treatment | Shot/sand blast, Polishing, Surface Passivation, Primer Painting , Powder Coating, ED- Coating, Chromate Plating, Zinc Plating, Dacromat Coating, Finish Painting |

Casting Size | 2 mm-2000mm / 0.08inch-79inch for casting iron, as per customer requirement |

Casting Weight | Range from 0.01kg-1000kg |

Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/ Reaming /Grinding/Honing and etc. |

Machining Tolerance | From 0.005mm-0.01mm-0.1mm |

Drawing Format | jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

Testing Machine | CMM, Digital Height Gauge, Caliper, Coordinate Measuring Machine, Projecter Machine, Roughness Tester, Hardness Tester and so on |

Certificate | ISO9001, CE, TUV, SGS or as your requirement to do test by the third party |

Packing | Plywood pallet, plywood box or as per your requirement |

Quality Control | Conducted by ISO9001 System and PPAP Quality control documents |

Service | Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

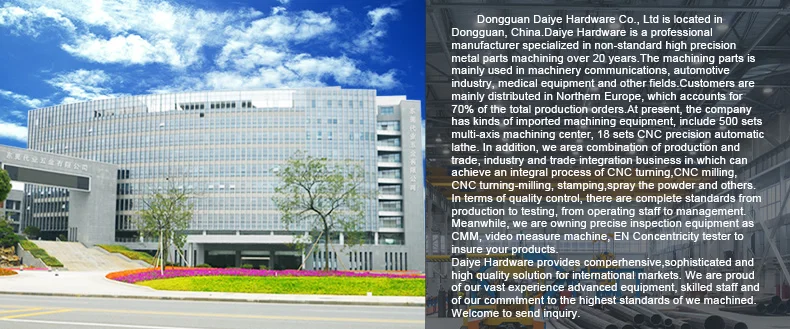

Company Profile

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q : Will my design drawings be safe when you get it ?

A : Yes, we will not publish your design to a third party unless your permission is obtained. We can sign NDA before you send the drawings.

Q : How to deal with surface treatment problems?

A: Sample color identification and dispensing ensure batch color consistency, strengthen manual inspection, avoid the defective products.

Q: How to avoid mass order quality problems?

A : Strengthen the prevention and inspection in advance of the process of production and processing, set important processes as the key point of quality control, follow up the inspection and defense throughout the process.

Q: Can you accept OEM or ODM ?

A: Sure. we have made OEM and ODM items for many customers. A professional development team to design new items are ready for you.

A: We are factory.

Q : Do you customize products according to our design drawings ?

A : Yes, we are a professional metal manufacturing factory with experienced engineering team, which can make customized products according to customer drawings.

Q : Will my design drawings be safe when you get it ?

A : Yes, we will not publish your design to a third party unless your permission is obtained. We can sign NDA before you send the drawings.

Q : How to deal with surface treatment problems?

A: Sample color identification and dispensing ensure batch color consistency, strengthen manual inspection, avoid the defective products.

Q: How to avoid mass order quality problems?

A : Strengthen the prevention and inspection in advance of the process of production and processing, set important processes as the key point of quality control, follow up the inspection and defense throughout the process.

Q: Can you accept OEM or ODM ?

A: Sure. we have made OEM and ODM items for many customers. A professional development team to design new items are ready for you.

There have been no reviews for this product yet.

Related products

$750.00

High Speed 3000W Electric Motorcycle Adults 80km/h Off Road Motorcycle Electric

Club Point:

0

$500.00

SKYTEAM 50CC 125CC 4 stroke PBR MONKEY ZB50 KSR Motorcycle (EEC EURO3 Approval)

Club Point:

0