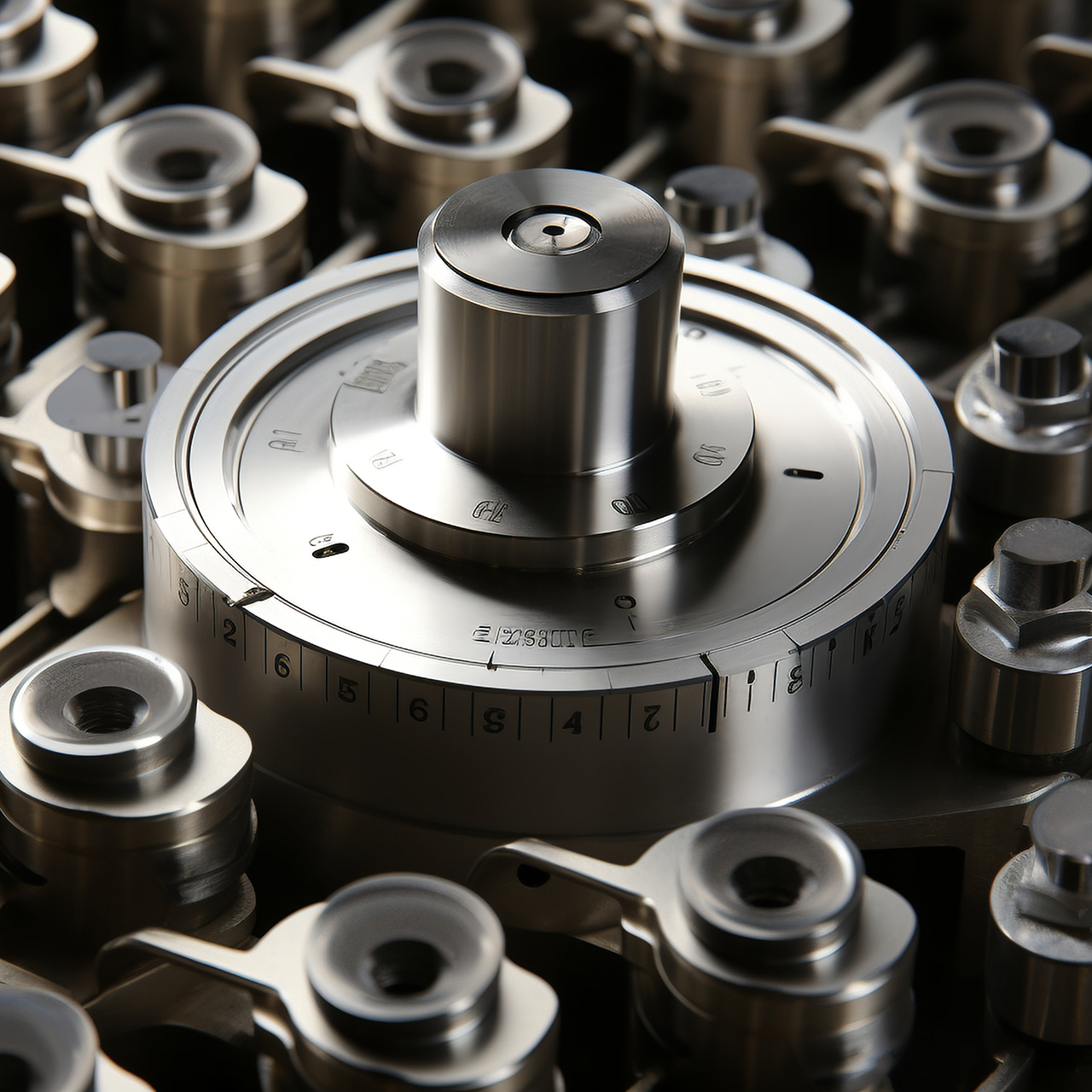

Aluminum 6061 6060 Cnc Machining Parts: Surface Oxide,Anodized Mechanical Auto Spare Parts

Inhouse product

-

G2000 Women Belted Dress

$53.90

About Us

Company Profile<<<

Shenzhen juke precision electromechanical Co., Ltd., headquartered in Shenzhen, was established in May 2008. At the same time, it also has a trading company in Hong Kong and a processing factory in Chengdu. We are a factory with 14 years of precision manufacturing experience. We strictly follow the iso901:2008 quality management system, with scientific management mode, advanced inspection equipment and strict quality requirements, so that the company's product quality leaps to the forefront of its peers; Passed the British GIC ISO9001:2008 quality system certification in November 2012; We are engaged in precision molds, CNC turning parts and CNC milling parts. We can make products with various materials, such as stainless steel, steel alloy, copper, aluminum, POM, bakelite, nylon, etc. We have and are not limited to anodizing, black oxidation, high polish and electroplating. We also import our machines from China Taiwan and Japan to ensure the critical size. The minimum tolerance we can do is 0.005-0.01 mm. Juke always adheres to the policy of "quality first, responsible management", and creates high quality with the highest precision and continuous R & D spirit High efficiency, has established good business relations with customers in the United States, Canada, Japan and Singapore.

Cooperating with us, we believe that with high-quality service and high-quality products, we can bring you huge profits

FACTORY

Our Advantages

Certificate

FAQ

Q1: I'd like to know your business scope and what products you export?

A1: Geekee company is a professional manufacturing company focusing on the design and production of precision parts, testing and assembly fixtures, as well as CNC machining centers and CNC automatic lathes. The exported products are mainly the processing and production of raw materials according to the drawings provided by customers, not limited to certain products.

Q2: Are you a factory or a trading company? Is it capable of mass production?

A2:We are factory direct sales, with more than 200 employees and experienced engineers. We have factories in Shenzhen and Chengdu respectively. Our company has more than 120 CNC production equipment, large-scale production capacity, a variety of testing equipment and professional quality inspection personnel, which can ensure product quality and meet the needs of customers for large quantities of orders.

Q3: How can I get an offer?

A3:First, you need to provide order drawings. You can provide product drawings in PDF format. It would be better to provide step or Igs. Our engineers will review the drawings and formulate a set of production process. We will make corresponding quotations according to this. This stage will take some time. Please wait patiently. Quotation methods: EXW, FOB, CIF, etc. generally, we adopt fob for foreign trade quotation.Of course, if you don't have drawings, can you provide samples? We can copy and provide you with better solutions. Send us pictures or drafts with product dimensions, and we can also try to make CAD or 3D files for you.

Q4: If I provide you with drawings, can you guarantee that the drawings will not be leaked?

A4:We will keep the drawing information strictly confidential and disclose it to a third party without permission. Willing to sign confidentiality agreement if necessary.

Q5: Can we get some samples before mass production?

A5:Of course, you can contact us. (we need to pay a certain amount of material fees and freight, which we are willing to return when mass production is carried out)

Jiangyin Ou-rene Top Precision Machining Stainless Steel Aluminum Brass Parts Metal CNC Service Machined Lathe Turning Milling

Product details

| Material | Aluminum Alloy |

| tolerance | Generally ± 0.01mm, especially ± 0.002mm |

| Surface treatment | Anodizing,Plating,Painting,Polishing,Smooth,etc |

| MOQ | 1 Piece |

| Quality control | 100% QC Inspection |

| delivery | DHL Fedex TNT UPS Seashipment |

| Drawing Format | STP. STEP . IGS . PRT . X_T, PDF |

| Equipment | CNC Machining,turning Centres,EDM,WEDM, Etc |

| Our Service | OEM&ODM CNC machining,as per customer's requirement |

| keyword | CNC machining |